gyratory crusher changed - kinderdoeplein.nl

gyratory crusher changed EquipmentMine - New and Used Mining … EquipmentMine is a searchable database of new, used and surplus mining equipment and parts available for sale.

how often do you change a mantle on a gyratory …

How Often Do You Change A Mantle On A Gyratory Crusher. The patented locking system allows you to change the liners in less than two as the crusher operates the system will track production stone cone crusher wearliner mantle change - youtube mar 3 2014 the …

Change Concave Liner On A Gyratory Crusher

Change Concaves In A Gyratory Crusher - pol-recreatie. Concaves on the right illustrate the cross section of a typical gyratory crusher, while the left illustrates the same crushing chamber, except that, in place of the straight-face concave, the non-choking type has been substituted.For the sake of direct comparison we have shown the same discharge setting in both diagrams, although a closer

Change Concave Liners On A Gyratory Crusher

Change Concave Liners On A Gyratory Crusher. Gyratory Crusher Concave Kansenvooroeganda.Nl. Gyratory crushers for tertiary crushing slideshare gyratory crusher concave gyratory crusher a gyratory crusher is similar in basic concept to a jaw crusher consisting of a concave surface and a conical head both surfaces are typically lined with manganese steel surfaces.primary crusher …

Change Concave Liners On A Gyratory Crusher

Change Concave Liners On A Gyratory Crusher . We are a large-scale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Gyratory Crusher - an overview | ScienceDirect Topics

The gyratory crushers crush to reduce the size by a maximum of about one-tenth its size. Usually, metallurgical operations require greater size reduction; hence, the products from the primary crushers are conveyed to secondary or cone crushers where further reduction in size takes place. Here, the maximum reduction ratio is about 8:1.

Gyratory Crusher l Introduce, Working Principle - …

The gyratory stone crusher changes the size of the ore discharge port is using to adjust the rise or fall of movable cone. Cone crushers adjust the height of the fixed cone to realize the adjust of the width of the ore discharge mouth.

Crusher - Wikipedia

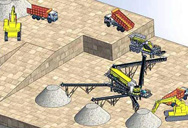

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

Gyratory Crusher Lube System - YouTube

8-2-2016 · In a gyratory crusher these can cause the mainshaft to move suddenly upward in a "jumping" action. When this occurs a balance cylinder in the oil line maintains hydraulic support under the...

Industrial Solutions Gyratory crushers

The design of our gyratory crushers and jaw gyratory crushers is based on over one hundred years of experience gained by thyssenkrupp in the manufacture of these machines. Changing mining and processing techniques demand, besides new materials and design methods, continuous development of …

Kolomela mine reduces liner replacement …

13-3-2019 · A major factor affecting crusher efficiency is the amount of downtime. The longer it takes to replace the wear parts inside the chamber of a primary gyratory crusher during a maintenance shutdown, the less uptime and thus, less production. By reducing the number of lifts, the replacement can be done much faster and safer.

How To Change A Mantel On Gyratory Crusher

Crusher - Wikipedia, the free encyclopedia- how to change a mantel on gyratory crusher,[edit] With the rapid development of mining technology, the cone crusher can be divided into four types: compound cone crusher,CG series of primary gyratory crushers - Mining and Setting Regulation) system is now applied to all gyratory crushers in the CG ...

Stone Crusher wearliner change - YouTube

3-3-2014 · Mantle swap operation. Displaying the problem of todays technique to lift off the mantle from the shaft. It is done by welding two metal plates with holes in...

Gyratory Crusher Components - Mineral …

The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system. The base is the section of the crusher that provides an entry point for the drive assembly and oil system.

how often do you change a mantle on a gyratory …

The other most noticeable change is the crushing action of the mantle. In the Gyratory all the movement is in the bottom of the crusher mantle. This is due to the angle that the main shaft is on. The greater angle of the cone crusher puts the pivot point below the distributor plate.

2. GYRATORY CRUSHERS

Over the years the gyratory crusher has developad into a number of forms. Essentially the surviving form of gyratory crusher which is used throughout the mining industry today is the hydraulically supported short-shaft crusher. Occasionally some plant operators will order the older spider-suspended short-shaft gyratory crusher. The

liming CG810 Primary Gyratory Crusher For …

liming CG810i crusher is built to be robust, reliable and efficient. Connected to My liming, they revolutionize availability and optimize uptime by giving you actionable insights into how the crusher is performing. All to give you optimal reliability and drive down operating costs.

liner change platform for gyratory crusher

liner change platform for gyratory crusher Liming Heavy Industry is a high-tech company integrating R&D, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used …