vibrating conveyor system design - trapkroeg.nl

Conveyor system. Vibrating conveyor systems A vibrating conveyor is a machine with a solid conveying surface which is turned up on the side to form a trough They are used extensively in food-grade applications to convey dry bulk solids where sanitation, washdown, and low maintenance are essential Vibrating conveyors are also suitable for harsh, very hot ...

design vibrating conveyor system

design vibrating conveyor system [email protected] Vibro Industries - Air Operated Transporter Conveyor. Over the last 51 years, Dorner’s product line has evolved from a single, low profile metalworking conveyor to a robust line of industrial, sanitary, and automation precision conveyors.

All About Vibrating Conveyors - Types, Design, and …

23-08-2020 · Conveyor technology has been developed to move all kinds of product, whether it be solid, semi-solid, or even liquid, and many conveying systems are available to address each of these needs. Our article on understanding conveyor systems does a great stone of showing these different conveyor types, but in this article, we will focus in on vibrating conveyors and their types, designs, and uses.

Vibrating Conveyors - Kinergy

Design Features of the Kinergy Driven Vibrating Conveyor. Kinergy has the most advanced vibratory machine technology available. Our designs include the following: Durability: Kinergy Vibrating Conveyors are built to last with an average of 20 or more years of productive use.

Vibratory Conveyors

For more than 50 years Renold AJAX Vibrating conveyors have been used in a variety of industry applications for transferring many types of granular and bulk materials. Renold Ajax conveyor systems can also be modified to perform other functions such as screening, scalping, drying, cooling, grading and dewatering. Renold custom designs

Vibratory Conveyors | Vibratory Conveyor Systems …

Electromagnetic Vibratory Conveyor: The Smalley EMC2+ represents the cutting edge in vibrating conveyor technology and design. We offer 50 plus years of expertise bringing world class technology, reliability and versatility to the next generation of Vibrating Conveyors. Instant Start and Stop, either manually or remote.

Vibrating Conveyors uses for the bulk material …

vibrating conveyors #SEP004 is an instrument that uses vibration to “feed” material to a process or machine.They are mainly used to transport a large number of smaller objects to the belt conveyor, bucket elevator, multi-head weigher etc.. Standard Hopper volume: 800mm X …

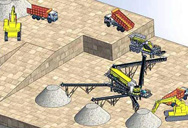

Conveyor system - Wikipedia

11-09-2007 · A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industries.

Vibrating Conveyors

CoilWeb® Vibrating Conveyors DESIGN BENEFITS ... or resonant frequency of the pan-spring system is nearly the same as the operating frequency of the conveyor, ... Selecting the proper size and type of vibrating conveyor is based on the following three factors: 1. Quantity of material to be conveyed.

design vibrating conveyor system - Cuppen …

design vibrating conveyor system. design vibrating conveyor system [email protected] Vibro Industries - Air Operated Transporter Conveyor Over the last 51 years, Dorner’s product line has evolved from a single, low profile metalworking conveyor to a robust line of industrial, sanitary, and.

Vibrating conveyors | Bruks Siwertell

Vibrating conveyors can form part of complex processing facilities and are easily customized to meet varying needs. They are ideally paired with our Bruks screening systems. Integral screens are often incorporated into a conveying system and can efficiently separate over-sized or fine particles during material transfer.

Vibratory Conveyors

Table of ContentsClassification of Conveyor TypesMaterial Movement along Conveyor TroughTrough Amplitudes and Forces for Different Drive Mechanisms Vibratory or oscillating conveyors can be found in all types of industry, handling virtually any granular bulk material. They can be combined with other process functions, such as screening, cooling, drying and de-watering, while conveying. The ...

Vibratory Conveyors - Alvibra: Vibrating Conveyor

Vibrating conveyor - closed Vibrating conveyor - closed ; ... (ATC) is a unique, robust and effective vibratory conveyor using a closed tube design, well suited when the requirement is a closed and dust proof transport system and a sanitary design that is easy to clean.

Vibratory Conveyor - YouTube

24-07-2017 · Vibratory Conveyor (Natural Frequency) - Duration: 0:29. Sharp Systems Ltd 15,213 views. 0:29. Development of Multi Crop Cleaner and Grader: ... Inclined Vibrating …

Vibrating Conveyor Design - bulk-online.com

10-01-2015 · Also the designer needs to be well versed to vibration engineering (motion, forces, resonance, tuning ratio, etc. as per engineering textbooks) to decide proper spring support system. The vibrating conveyor can have a spring system of flat plate type, helical springs or torsional springs. As said above actual and proper design is complex.