How Does a Jaw Crusher Work | Jaw Crusher | Kemper Equipment

Double toggle movement jaw crushers like the Blake style (named for the inventor of the first successful mechanical jaw crusher, Eli Whitney Blake), have long been the standard used for crushing hard and abrasive rocks, as well as sticky feeds. These jaw crushers have high energy efficiency.

Bucket crusher - Wikipedia

Bucket crushers are primarily employed in mining and demolition for the breaking-down of crude minerals, concrete and masonry. During the crushing process, the crusher bucket is positioned vertically so that the crushed material can be released. The jaw bucket works with the hydraulic system of …

Jaw Crushers

Employed as a primary crusher, the overhead eccentric jaw crusher is used in quarries, cement plants, aggregate plants and other installations. In addition to limestone, these units are used on dolomite, quartz, gravel, trap rock and ores. In some instances, a choice must be made between using this overhead eccentric model or our double toggle jaw crusher. Given your material specifications

Jaw Crushers | McLanahan

A Jaw Crusher uses compressive force for breaking material. This mechanical pressure is achieved by the crushers two jaws dies, one of which is stationary and the other is movable. These two vertical manganese jaw dies create a V-shaped cavity called the crushing chamber, where the top of the crushing chamber is larger than the bottom.

5 Common Questions about Jaw Crushers Answered | For ...

May 30, 2019 · Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart. The benefit that cone crushers offer over jaw crushers is …

Jaw crushers - liming

Jaw crushers are a popular alternative to primary gyratory crushers, since they can process large amounts of hard material efficiently. For 45 years, liming C Series jaw crushers have proven their reliability in different primary crushing operations in aggregates, mining and recycling applications, with up to 11,000 jaw crusher installations.

Mobile Crusher | Mobile Jaw & Impact & Cone Crushers ...

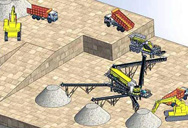

Especially for the operation of crushed stone such as highways, railways, hydropower projects. The tyre crushing machine and tracked crusher are two types of portable crushing. According to the needs of working, JXSC products mobile jaw crusher, impact crusher, cone crusher, and screen equipment. All model of JXSC mobile crushers

Jaw Crushers - MEKA Crushing & Screening Plants

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates. There are also primary and secondary types of these crushers.

Design and Construction of Rock Crushing Machine from ...

to smaller pieces. Rollers or jaw crushers are employed in this situation. The jaw crusher is a rocks or lumps reduction machine that employs two hardened manganese steel jaws, with one in relative motion against the other which is stationary while the roller crusher utilizes two …

Jaw Crushers - frogswitch.com

Jaw Crushers: Top Quality Movable and Stationary Jaw Plates . We produce movable and stationary jaw plates for all major brands of crushers, including: Allis-Chalmers; Svedala; Austin Western; Cedarapids; Hewitt-Robins; Kue-Ken; Missouri-Rogers; liming; liming; Pioneer; Telsmith; Universal; Many other machines - please call to inquire about your particular brand

liming Mobile Jaw Crusher Closed Side Setting (CSS) range ...

Use the jaw crusher reverse function on the display screen to get the arrow on the flywheel in the correct position. Always measure the CSS with the arrow on the flywheel pointing upward so that there is no confusion with subtracting strokes. Take care around the flywheels as the balance weights may rotate the flywheels at any time.

Crushers - MEKA Crushing & Screening Plants

MEKA Jaw Crushers are available in stationary and mobile applications. They are suitable for all heavy duty primary crushing needs for extremely hard rocks with their high quality cast steel pitman combined with a welded frame construction.

Suitable Crushers Employed in Construction Waste Disposal ...

The crushing station removes the iron part which is contained in the screened building wastes through the specific iron removal equipment. After that, the materials will be processed into a certain size of the regeneration of sand and gravel aggregate with a certain size through crushing machines like primary crusher and fine crusher.

Single VS Multi-Stage Crushing

Frequently this will be the case where a primary jaw crusher is to be followed by a gyratory machine. On the other hand, if the primary is a large gyratory, and the full output of this crusher is to gauge the. output of the plant, it will be necessary to install a, battery of two or more gyratories for the secondary reduction.

Crusher - Wikipedia

A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber.