resulting product is a grinding process

Resulting Product Is A Grinding Process. resulting model simulates the product size distributions as a function of energy input quite accurately. A noteworthy observation is that, unlike in ball mill grinding, the breakage rate. Live a Chat; the apparent solubility of ursodeoxycholic acid in the grinding process. grinding process was evaluated.

resulting product is a grinding process - unic-jean …

The resulting product, ... This grinding process serves to homogenize the ... Ethnic products are "in," so tortilla chips can be thankful for their Latin American ... Get Quote. The Benefits of Gear Honing - Gear Technology Honing. The Benefits of Gear Honing. ...

resulting product is a grinding process

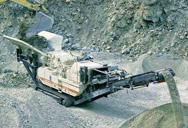

HGT Gyratory Crusher. Choosing the Right Grinding System for (Processing) Thus to define the grinding operation which should take place subsequently we must always take the behaviour and the properties of the product resulting from this process into account One possibility is that the pigment already presents very fine elementary particles and the only subsequent process necessary is ...

resulting product is a grinding process - …

What Is Grinding Process In Mining Pdf - istcompazzanoxit. The product quality and fineness achieved in a grinding or dispersion process is constant if the feed particles and the resulting fragments are stressed similar → type of stress (eg impact or compression and shear) each feed particle and the resulting fragments. 【service online】

Grinding Machining Process : Complete Notes - …

This process is known as Dressing of grinding wheel and the whole process takes 15 to 20 minutes to operate. The life of the grinding wheel is described as the time period between two successive dressings. Grinding operation is one of the machining processes which consume the highest specific cutting energy with very less material removal rate.

Corrosionpedia - What is Grinding? - Definition …

13-6-2018 · Grinding is a subset of cutting, as grinding is a true metal-cutting process. Grinding is very common in mineral processing plants and the cement industry. Grinding is used to finish workpieces that must show high surface quality and high accuracy of shape and dimension.

Process design of the patterning process of profile ...

1-1-2019 · Subsequently, the patterning process can increase the relative material removal rate, while maintaining the forces. Figure 8. Influence of the patterns on the resulting grinding forces. In this study, the influence of the patterns on the grinding process increases with increasing stone size.

Grinding (abrasive cutting) - Wikipedia

Grinding is a subset of cutting, as grinding is a true metal-cutting process. Each stone of abrasive functions as a microscopic single-point cutting edge (although of high negative rake angle), and shears a tiny chip that is analogous to what would conventionally be called a "cut" chip (turning, milling, drilling, tapping, etc.) [citation needed].

Grinding machine - Wikipedia

A grinding machine, often shortened to grinder, is one of power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool.Each stone of abrasive on the wheels surface cuts a small chip from the workpiece via shear deformation.. Grinding is used to finish workpieces that must show high surface quality (e.g., low surface roughness) and high ...

Grinding Characteristics of Wheat in Industrial Mills

seeds to fine grinding of the resulted milling products, after their sorting in fractions of dif‐ ferent sizes. The first technological phase of grinding process, in wheat mills, is gristing or coarse grinding phase, which also consists of several technological passages.

Basics of Grinding - Manufacturing

The Grinding Process Grinding is a material removal and surface generation process used to shape and finish components made of metals and other materials. The precision and surface finish obtained through grinding can be up to ten times better than with either turning or milling. Grinding employs an abrasive product, usually a rotating wheel ...

Grinding burn - Preventing and Monitoring! – …

The term grinding burn while grinding is understood as the thermal damage of a ground part caused by an incorrect grinding process. Grinding burn is caused by excessive heat dissipation into the part material. As materials cool as rapidly as they heat, the material undergoes a treatment similar to a tempering process.

GRINDING AND OTHER ABRASIVE PROCESSES

Grinding Material removal process in which abrasive particles are contained in a bonded grinding wheel that operates at very high surface speeds •Grinding wheel usually disk-shaped and precisely balanced for high rotational speeds ... angles, resulting in low shear plane angles and high

Grinding | materials processing | Britannica

Other articles where Grinding is discussed: abrasive: Grinding: Grinding, the most important abrasive application, is in some way involved in the manufacture of almost every product. This use may be direct, as when the product requires pieces that must be made within close dimensional tolerance limits, or a very smooth surface, or…

Grinding Wheel: Specifications & Manufacturing …

29-5-2018 · Grinding is a machining process improving the surface finish of the stone and producing small chips. The tool used for this process is the grinding wheel. It is a cutting tool in which millions of microscopic abrasive grains are bond together. Here, each abrasive stone acts like a spiky tool.

Comminution processes: Basics and application to energy ...

Product related stress model for constant product qualities The product quality and fineness achieved in a grinding or dispersion process is constant if the feed particles and the resulting fragments are stressed similar → type of stress (e.g. impact or compression and shear) each feed particle and the resulting fragments are stressed equally

Grinding Process - Mineral Processing & Metallurgy

This preferential grinding would also suggest that the size distribution of the material after grinding would not be geometrically similar to that initially, but that a “tail” initially on the right-hand side of the curve would be reduced; this geometrical similarity between mill feed and product …

Grinding process - LinkedIn SlideShare

Grinding is a material removal process in the form of microchips accomplished by hard abrasive grits that are contained in a bonded grinding wheel rotating at very high surface speeds. The rotating grinding wheel consists of many cutting teeth ( abrasive particles ) and the work is fed relative to the rotating grinding wheel to accomplish material removal.

5 Facts About Grinding Processes - Monroe

Grinding is machining process that’s used to remove material from a workpiece via a grinding wheel. As the grinding wheel turns, it cuts material off the workpiece while creating a smooth surface texture in the process. While grinding sounds simple enough, there are probably some things you don’t know about this machining process.