How is Iron Refined from Ore? (with pictures)

29-04-2020 · Although iron does not occur in its pure form in nature, some kinds of ore contain up to 70% iron atoms. Iron ore consists of oxygen and iron atoms bonded together into molecules. To create pure iron, one must deoxygenate the ore, leaving only iron atoms behind, which is the essence of the refining process. In its natural form, iron ore has a ...

Steelmaking and Refining | Introduction to Chemistry

Steelmaking Overview. Steelmaking is the second step in producing steel from iron ore. In this stage, impurities such as sulfur, phosphorus, and excess carbon are removed from the raw iron, and alloying elements such as manganese, nickel, chromium, and vanadium are added to produce the exact steel …

Schematic Diagram Of Refining Of Iron Ore To Steel

Iron ore beneficiation equipment layout. . After years exploration in mining industry . and water works users can process . schematic diagram of refining of iron ore to steel. schematic diagram of refining of iron ore to steel . coal power plant process flow diagram excel . beneficiation phosphate rock diagram . …

schematic diagram of refining of iron ore to steel

Flow Diagram Process Of Mining And Refining Iron Ore. Iron processing, use of a smelting process to turn the ore into a form .. the narrowing of the range of particle sizes makes the gas flow more Schematic diagram of modern blast furnace (right) and hot-blast stove (left).

schematic diagram refining of iron ore steel

Iron ore to iron ore pellets24 Кб In order to produce steel, iron ore is required, in large quantiti Complete the table below, by adding notes and diagrams that represent the stages of mining iron ore and refining it into pellets, ready for the steel mill.

Blacksmithing - Refining iron bloom into wrought …

03-04-2018 · Refining an iron bloom into a new wrought iron bar! ... smelting ore - Duration: 22:47. cultuuramersfoort 1,036,005 views. 22:47. The Secrets of Wootz Damascus Steel - Duration: ...

Iron processing | Britannica

14-08-2020 · Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned.Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth’s crust, and it is the ...

Steelmaking - Wikipedia

Steelmaking is the process of producing steel from iron ore and/or scrap.In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur and excess carbon (most important impurity) are removed from the sourced iron, and alloying elements such as manganese, nickel, chromium, carbon and vanadium are added to produce different grades of steel.

Refining (metallurgy) - Wikipedia

15-01-2007 · The term refining is used in a narrower context. Henry Corts original puddling process only worked where the raw material was white cast iron, rather than the grey pig iron that was the usual raw material for finery forges. To use grey pig iron, a preliminary refining process was necessary to remove silicon.The pig iron was melted in a running out furnace and then run out into a trough.

Making Steel from Iron Ore - YouTube

12-11-2007 · Mike Blue, Randall Graham, Ric Furrer, making steel at Larry Harleys in May 2006. Lecture and Demonstration. Filmed by Christopher Price of The Tidewater Forge. 9 minutes.

Diagram Of Iron Ore Mining And Refining

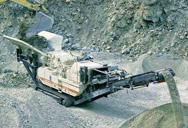

And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal, asphalt, gravel, concrete, etc. With more than 2,500 case sites, the scientific management method, the refined manufacturing process, and the innovative manufacturing concept,have rapidly grown into the mining machinery production and export bases in China even the world.

schematic diagram of refining of iron ore to steel ...

Gold Ore Refining … iron ore mining beneficiation processing flow chart. iron ore processing flow may be the front … Process Flows Diagram For Iron Ore Processing | Manganese Crusher. flow diagram of ore mining to refining process … circuit diagram for iron ore washing plant … Flow diagram for making steel from iron ore …

Schematic Diagram Of Steel By Refining Iron Ore

Refining Iron From Iron Ore Schematic DiagramBINQ Mining. Feb 17 2013 · a diagram of how iron ore is mined – CrusherGranite Crusher This page is provide professional a diagram of how iron ore is mined information for you Learn how iron ore is mined and eventually refined into things like steel More detailed. Read the rest >

refining iron ore to steel - mlinterier.eu

How iron is made. Iron ore is converted into various types of iron through several process , Pig iron has only limited uses, and most of this iron goes on to a steel mill where it is converted into various steel alloys by , The Ore Extraction and Refining Process...

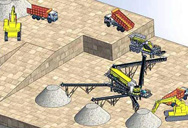

Iron Ore Processing for the Blast Furnace

Iron Ore Processing for the Blast Furnace (Courtesy of the National Steel Pellet Company) The following describes operations at the National Steel Pellet Company, an iron ore mining and processing facility located on the Mesabi Iron Range of Minnesota. Creating steel from low-grade iron ore requires a long process of mining, crushing,

Schematic Diagram Of Refining Of Iron Ore To Steel

schematic diagram of refining of iron ore to steel,Our company is a large-scale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing. We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusher, ball mill, sand maker, mobile crushing plant

Steel manufacture - SteelConstruction.info

Iron and steel making by-products. As with all large-scale manufacturing processes, the production or iron and steel generates by-products. On average the production of 1 tonne of steel results in 200 kg (EAF) to 400 kg (BF/BOF) of by-products. The main by-products produced during iron and crude steel production are slags (90%), dusts and sludges.

Steel Refining | Carmeuse

Refining at the Ladle Metallurgical Furnace is the last but the most important stage of the steel melting process. This stage gives steelmaker a final chance to refine the slag and adjust both the stone composition and temperature of the steel. There should be no compromise on the selection of fluxes, ensuring the highest quality possible.

Schematic Diagram Of Refining Of Iron Ore To …

Schematic Diagram Of Refining Of Iron Ore To Steel. Processing capacity:45 - 1814 t/h Feeding size: ≤ 314 mm Applied materials: River pebbles, granite, dolomite, basalt, iron ore, limestone, quartz stone, diabase, iron ore, gold mine, copper mine Get Price List