Images of cone crusher maintenance

Cone Crusher Maintenance

Cone Crusher - Tips of Operation and Regular Maintenance ...

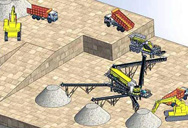

Aug 01, 2019 · In the mining industry, the most common crusher types are jaw crusher and cone crusher. Jaw crusher is usually used for primary crushing, and cone crusher is used for secondary crushing. The material of crusher plays an important role in its working efficiency and service life. However, the regular operation and maintenance …

Maintenance of Aggregate Crushers | Agg-Net

Performing regular maintenance on crushers is integral to the reliability, performance and output they achieve. Prevention is better than cure; by carrying out regular inspections operators will ensure that their crusher …

Cone Crusher Maintenance - Mineral Processing & Metallurgy

Cone Crusher Maintenance. Previous Next. WOBBLE PLATE FEEDER. A wobble plate feeder is furnished as standard equipment with Fine crushing chambers and as optional equipment …

Maintenance of Hydraulic System of Cone Crusher (2 ...

1. The crusher prevents excessive oil temperature The temperature of the hydraulic system of the hydraulic cone crusher is generally suitable in the range of 35 °C - 60 °C according to the experiment, and the maximum should not exceed 80 °C. At normal oil temperatures, the crusher hydraulic …

Avoid Unplanned Downtime: 5 Crusher Maintenance Best Practices

Feb 25, 2019 · To prevent machine failure, Schmidt offers tips on horizontal shaft impact (HSI) crushers and cone crushers. Perform Daily Visual Inspections. According to Schmidt, daily visual inspections …

operation and maintenance manuals for cone crusher

Cone Crusher Maintenance | Aggregates Manager. Jul 1, 2012 ... Performing regularly scheduled maintenance on cone crushers is the ... At the top of Thistles list is keeping the cone crusher choke …

Cone crusher basics in 4 minutes — liming Mining and Rock ...

The liming CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher…

Cone Plant Setup and Maintenance - YouTube

Apr 05, 2011 · Cone Plant Setup and Maintenance 1. Set up and Maintenance 2. Belt Drives and Oil Safety 3. Cone Adjust 4. Cone clearing system 5. Cone Lube System 6. Cone …

Maintenance - Jaw crusher Impact crusher cone crusher sand ...

Jaw crusher – Lubrication (1) To ensure normal operation and extend service life of the crusher, regular lubrication shall be performed. (2) Grease in the bearing block shall be …

liming® HP300™ cone crusher - liming

liming® HP300™ cone crusher is engineered to ensure maximum operator safety and easy maintenance. Accessibility from the top of the crusher to the principal components, easy access for liner maintenance, mechanical rotation of the bowl for removal with a simple press of a button, and no backing compound on liners make liming® HP300™ cone crusher safe to use and maintain.

liming HP100, HP200, HP300, HP400 AND HP500 CONE …

maintenance of crushing and screening equipment with regard to safety and operations. A copy of this manual must be provided to and studied by each person entering the machine areas of …

Stone Crusher wearliner change - YouTube

Mar 03, 2014 · Cone Plant Setup and Maintenance - Duration: ... 1:08:37. liming CM 1208i Crushers - Komatsu PC600LC - Volvo L220E - L110F and trucks ... The worlds largest cone crusher …

QH441-OperationManual - Crusher Works

39 Item Part No. Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)

Cone Crusher - Mineral Processing & Metallurgy

Fast Crusher Maintenance Reduces Downtime SIZE DESIGNATION The size of a Hydrocone crusher is designated in terms of the feed opening and the head diameter at the crushing …

liming Cone Crushers — liming Mining and Rock Technology

liming cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. They are equipped with the hydraulic Hydroset™ system, which provides safety and setting-adjustment functions. Our crusher automation system delivers real-time performance management, enabling you to monitor and optimize crusher …

Jaw Crusher VS Cone Crusher | Advantages and Disadvantages

Jaw crusher and cone crusher are usually arranged on the stone crusher plant in two stages. Jaw crusher breaks the rock to 10 ~ 30 cm size. Cone crushing machine further broke the stone to below 10 cm. Large cone crushers (gyratory crushers) also can as head crushers. Fine jaw crusher also can as a two-stage crusher…